RENOVATION AND HEAT INSULATION OF BUILDINGS

In the past ten years heat insulation of buildings is one of the topical themes in the field of construction. This naturally brings up multiple questions, asked by customers and experts:

Various combinations of questions and answers arise. And while the client becomes an expert in the area of heat insulation, someone has offered a lower price and this has led to the end result. Cracking of the ground coat starts after one or two winters, as well as complete ripping off of the reinforcing mesh or falling of individual sheets.

While the actual price is about 45 BGN per square meter, many “experts” offer the service for 25 BGN per square meter (labour and materials). For me, as a person engaged in this industrial branch, the following questions remain: What materials is an order fulfilled with for such a price? What is the quality of performance? Does the worker giving this price offer a long-term warranty for the investor, and does he observe the safety standards, adopted in industrial alpinism?

- External or internal insulation?

- EPS or XPS?

- Two or eight centimetres thickness of the entire system?

- Structural, polymeric or general plaster?

- Paint or first coat?

- One or two first coats?

- With or without preliminary ground-coat application on the façade?

Various combinations of questions and answers arise. And while the client becomes an expert in the area of heat insulation, someone has offered a lower price and this has led to the end result. Cracking of the ground coat starts after one or two winters, as well as complete ripping off of the reinforcing mesh or falling of individual sheets.

While the actual price is about 45 BGN per square meter, many “experts” offer the service for 25 BGN per square meter (labour and materials). For me, as a person engaged in this industrial branch, the following questions remain: What materials is an order fulfilled with for such a price? What is the quality of performance? Does the worker giving this price offer a long-term warranty for the investor, and does he observe the safety standards, adopted in industrial alpinism?

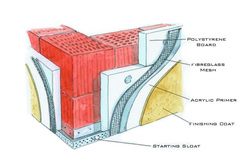

TECHNOLOGICAL SCHEME

For the work season of 2013 TBM Service Ltd offers the following technological scheme for production of a heat insulation system:

1. Application of a ground coat on the foundation for sticking with organic based conservation ground coat (only for brick facades or foundations subjected to strong winds)

2. Gluing of 5-6 cm EPS sheets (according to a preliminary agreement with the investor)

3. Wall plug placement on the sheets - 3-6 wall plugs per square meter

4. First coat with a mesh - 145 g/m2

5. Finish coat without a mesh.

6. Application of a conservation plaster or paint. The used materials are produced by the following companies:

- Ground coat BORO Ltd

- EPS BASF

- Mesh Baumit Ltd

- Gluing and plastering mixture Baumit Ltd

The conservation paints and plasters shall be additionally negotiated based on the choice of the investor.

1. Application of a ground coat on the foundation for sticking with organic based conservation ground coat (only for brick facades or foundations subjected to strong winds)

2. Gluing of 5-6 cm EPS sheets (according to a preliminary agreement with the investor)

3. Wall plug placement on the sheets - 3-6 wall plugs per square meter

4. First coat with a mesh - 145 g/m2

5. Finish coat without a mesh.

6. Application of a conservation plaster or paint. The used materials are produced by the following companies:

- Ground coat BORO Ltd

- EPS BASF

- Mesh Baumit Ltd

- Gluing and plastering mixture Baumit Ltd

The conservation paints and plasters shall be additionally negotiated based on the choice of the investor.